HDPE Pipe Supplier strategies for cost-effective infrastructure solutions

Discovering the Leading Pipeline Manufacturers: Top Quality, Integrity, and Technology

The pipeline manufacturing industry stands at the intersection of innovation, integrity, and top quality, driven by leading firms such as Tenaris and Vallourec. These manufacturers are not just dedicated to creating high-performance products yet are additionally introducing sustainable practices that address modern-day environmental worries. As we check out the standards that define excellence in pipeline services, it ends up being obvious that the landscape is swiftly advancing. What specific advancements are emerging, and just how are these advancements forming the future of pipeline facilities? The answers may redefine sector requirements in ways that are not yet totally recognized.

Leading Manufacturers Review

In the domain of pipeline manufacturing, a number of vital players become leaders, each contributing significantly to the industry's landscape. Firms such as Tenaris, Vallourec, and JFE Steel have developed themselves as frontrunners by regularly providing top notch items that satisfy strict industry standards. Tenaris, renowned for its ingenious remedies, concentrates on seamless and welded pipelines, providing primarily to the oil and gas market. Vallourec, a French international, focuses on the manufacturing of costs tubular remedies, stressing sustainability and progressed technology in its manufacturing processes.

JFE Steel, a major Japanese manufacturer, is recognized for its extensive array of steel pipelines, particularly those utilized in energy and facilities jobs. Their dedication to research and advancement has allowed them to generate high-performance materials that stand up to rough ecological conditions. Additionally, business like U.S. Steel and National Oilwell Varco have increased their market existence by diversifying their product offerings and enhancing functional efficiencies.

These leading producers not just control the market yet additionally drive development within the industry, setting standards for quality and reliability that other gamers strive to attain. Their contributions are crucial for fulfilling the raising need for reliable and durable pipeline solutions worldwide.

Standards for Top Quality Analysis

Quality evaluation in pipeline manufacturing rests on 2 critical criteria: material durability criteria and manufacturing procedure effectiveness. Making sure that materials satisfy strenuous sturdiness criteria is crucial for the long life and dependability of pipelines. In addition, enhancing the manufacturing procedure can boost productivity while maintaining high top quality, inevitably influencing total efficiency and safety.

Material Resilience Criteria

Assuring the durability and dependability of pipeline products is essential for maintaining infrastructure integrity and operational performance. Material durability standards play a vital role in evaluating the top quality of pipelines, determining the efficiency and life-span of the materials utilized in construction. Manufacturers should comply with a series of strenuous criteria, consisting of those established by organizations such as ASTM International and the American Petroleum Institute (API)

These criteria examine different factors, consisting of corrosion resistance, tensile stamina, and fatigue efficiency. As an example, pipes used in destructive environments need materials that can stand up to chemical destruction, while those subjected to high-pressure conditions should exhibit phenomenal tensile stamina.

Furthermore, aspects such as temperature level changes and environmental conditions must be taken into consideration, as these can significantly affect material habits over time. Manufacturers usually utilize sophisticated screening methodologies, consisting of sped up aging examinations, to mimic long-term wear and warranty that materials exceed or satisfy market standards.

Manufacturing Process Performance

Manufacturers' ability to enhance producing process efficiency is crucial for generating high-quality pipes that fulfill stringent industry requirements. Performance in manufacturing straight influences price monitoring, manufacturing timelines, and overall product honesty. To attain this, leading pipeline makers carry out sophisticated methods such as lean manufacturing, automation, and real-time information analytics.

Lean producing principles are vital in decreasing waste and taking full advantage of source usage. By improving procedures and removing redundancies, manufacturers can boost productivity while making certain consistent quality. Automation innovations, including robotics and computer system mathematical control (CNC) makers, play a pivotal duty in enhancing precision and reducing human mistake, consequently elevating the reliability of the last product.

In addition, making use of real-time information analytics permits producers to check production processes continually, enabling them to identify bottlenecks and make prompt changes. This proactive technique not just improves efficiency yet also supports high quality assurance procedures by making certain conformity with regulatory standards.

Reliability in Pipeline Solutions

Dependability in pipeline solutions is extremely important, as it straight affects the safety and performance of liquid transport systems. Trick aspects include the toughness of materials made use of, adherence to rigorous screening and certification requirements, and the incorporation of cutting-edge material remedies that boost performance. Comprehending these elements is vital for suppliers intending to deliver reliable pipeline facilities.

Importance of Longevity

Achieving longevity in pipeline solutions is crucial, as it straight affects the lasting performance and safety and security of facilities. Sturdy pipes are crucial for lessening maintenance expenses and decreasing the likelihood of catastrophic failures. This integrity is especially crucial in industries such as oil and gas, water supply, and wastewater administration, where the repercussions of pipeline failure can be severe, both financially and eco.

The products and producing processes employed by pipeline makers play a significant role in establishing the sturdiness of the final product. Utilizing top quality resources, advanced technologies, and cutting-edge design concepts ensures that pipelines can stand up to different stress factors, including stress fluctuations, temperature variations, and destructive settings.

Moreover, the longevity of pipes is very closely connected to their capability to withstand exterior aspects such as soil movement, seismic activity, and chemical exposures. Reliable rust defense approaches, such as finishings and cathodic protection, additionally enhance the durability of pipelines, protecting them against wear and tear over time.

Purchasing sturdy pipeline services eventually converts to increased operational efficiency, decreased downtime, and enhanced safety and security, affirming the crucial relevance of longevity in contemporary pipeline manufacturing.

Testing and Accreditation Criteria

In the domain of pipeline solutions, strenuous testing and qualification criteria are important to guarantee the reliability and safety and security of infrastructure. These standards work as benchmarks for examining the performance and toughness of pipeline materials and systems, validating they fulfill particular regulative and sector needs.

Checking procedures normally incorporate different techniques, including stress screening, hydrostatic analyses, and non-destructive screening techniques. These assessments are vital for identifying potential weak points or issues in the materials before they are deployed in real-world applications. Additionally, certification by recognized companies assurances that makers follow developed guidelines, which promotes count on amongst stakeholders, including end-users, designers, and contractors.

Several leading pipeline producers take part in continual surveillance and renovation of their testing methods to adjust to progressing sector criteria and technological improvements. Compliance with standards such as ASTM, ASME, and ISO not only boosts product dependability however additionally reduces the danger of ecological incidents related to pipeline failings.

Ingenious Material Solutions

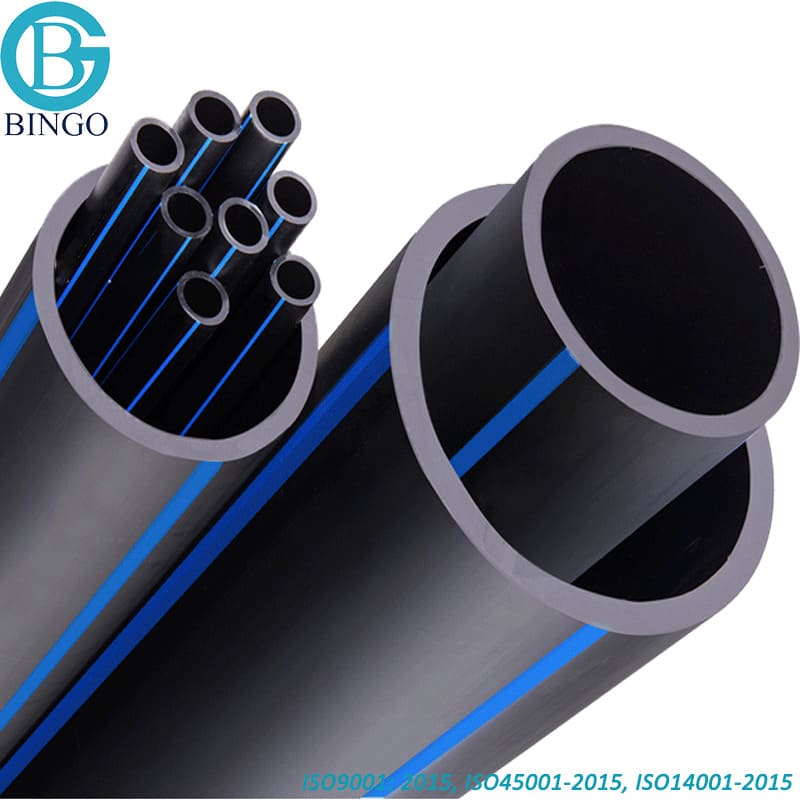

The development of cutting-edge product services has transformed the landscape of pipeline manufacturing, boosting both performance and toughness. Advanced materials such as high-density polyethylene (HDPE), cross-linked polyethylene (PEX), and composite products have actually become game-changers, using exceptional resistance to rust, temperature fluctuations, and stress variations. Texas Pipeline Manufacturer. These products not only extend the life-span of pipelines however likewise minimize maintenance costs, making sure reputable long-lasting performance

Sustainability is one more essential emphasis, with producers exploring bio-based composites and recyclable materials that lessen environmental impact. As governing requirements proceed to advance, the emphasis on innovative material solutions ends up being critical in meeting strict safety and security and ecological requirements. Ultimately, these improvements not only enhance the integrity of pipeline systems yet likewise add to the general efficiency and sustainability of energy transportation infrastructures.

Developments in Pipeline Technology

Innovations in pipeline modern technology are changing the industry by improving effectiveness, safety, and environmental sustainability. Recent advancements concentrate on wise pipeline systems that utilize sensing units and IoT innovation to monitor problems in real time, making it possible for proactive upkeep and reducing the risk of failures. These systems can spot leaks, Visit Website stress adjustments, and other anomalies, permitting quick response and reducing environmental impact.

Additionally, the growth of sophisticated products, such as composite and corrosion-resistant alloys, significantly extends the life-span and reliability of pipes. These materials decrease maintenance costs and improve performance in rough settings, making them excellent for gas, oil, and water transport.

In addition, automation and robotics are playing an essential function in pipeline building and examination (American Plastics LLC HDPE Pipeline Manufacturer). Drones and robot devices promote studies and assessments of hard-to-reach locations, making sure thorough assessments without jeopardizing security

Cutting-edge layouts, such as modular pipeline systems, permit for higher flexibility in setup and modification, catering to the dynamic requirements of the energy industry. With each other, these technological improvements not just boost functional efficiency yet additionally add to an extra lasting and durable pipeline framework, leading the way for a greener future.

Study of Success

Across various fields, successful executions of advanced pipeline technologies show considerable renovations in operational effectiveness and safety. One noteworthy instance is the release of smart pipeline surveillance systems in the oil and gas sector, where real-time data analytics have reduced leak detection times by over 50%. This not just minimizes environmental risks but likewise improves the general stability of pipeline facilities.

One more exemplary case is discovered in the water distribution market, where the setup of advanced materials, such as high-density polyethylene (HDPE), has caused a marked decline in pipeline corrosion and upkeep expenses. A major city reported a 30% reduction in water loss as a result of leakages after updating its aging pipeline network with these innovative products.

In addition, a major manufacturer implemented robot inspection innovations in its pipeline upkeep procedures, causing a 40% renovation in examination effectiveness. This technique has structured maintenance routines and considerably decreased downtime.

These case studies highlight exactly how prominent pipeline makers are leveraging advanced technologies to cultivate reliability and functional quality, eventually setting brand-new requirements for the industry (HDPE Pipe Supplier). As these successes remain to unfold, they lead the way for additional improvements in pipeline manufacturing and management

Ecological Sustainability Practices

Regularly, pipeline makers are prioritizing ecological sustainability methods to alleviate their eco-friendly impact and improve the long life of their products. This dedication is mirrored in different efforts intended at reducing waste, saving power, and utilizing lasting materials throughout the manufacturing process.

Many makers are adopting innovative technologies that decrease discharges and power usage. For example, the integration of automated systems and energy-efficient machinery helps streamline manufacturing while lowering reliance on nonrenewable fuel sources. Additionally, companies are significantly transforming to eco-friendly materials, such as recycled metals and bioplastics, which not only minimize the ecological impact however additionally promote a circular economic situation.

Additionally, pipeline makers are executing extensive lifecycle evaluations to evaluate the ecological implications of their items from inception to disposal. This approach allows them to determine chances for enhancement and foster responsible sourcing and waste administration techniques.

Partnership with ecological companies further enhances these initiatives, as suppliers seek to align their procedures with international sustainability objectives. Ultimately, these ecological sustainability techniques not just add to a much healthier planet yet additionally setting makers as liable leaders in the market, attracting environmentally aware stakeholders and consumers alike.

Future Trends in Pipeline Manufacturing

As the demand for more lasting and effective framework expands, pipeline manufacturing is poised for substantial developments that will certainly improve the sector. Key patterns anticipated in the coming years include the combination of sophisticated materials, such as corrosion-resistant and composite alloys, which improve resilience while decreasing ecological influence. Manufacturers are likewise expected to adopt ingenious manufacturing techniques, like additive manufacturing and automation, to improve processes, reduce waste, and reduced prices.

The surge of clever pipeline technologies, incorporating sensing units and IoT tools, will allow real-time monitoring and predictive maintenance, consequently boosting safety and functional efficiency. This electronic transformation will certainly not only enhance resource administration however additionally assist in conformity with rigid environmental regulations.

Sustainability will continue to be a main emphasis, driving makers to purchase eco-friendly techniques, including energy-efficient production approaches and recycling campaigns. As the international emphasis on climate modification escalates, pipeline manufacturers will certainly need to adjust by developing remedies that satisfy both environmental and economic demands.

Frequently Asked Questions

What Industries Primarily Use Pipeline Products From These Manufacturers?

Pipeline items are mostly utilized in industries such as oil and water, wastewater and gas management, chemical handling, mining, and building and construction. These fields rely on reliable, resilient, and safe transportation of products and liquids.

How Do Manufacturers Make Certain Compliance With International Pipeline Standards?

Manufacturers assure compliance with international pipeline criteria by implementing rigorous high quality control processes, carrying out normal assessments, sticking to well-known regulatory frameworks, and buying staff member training to advertise understanding and understanding of safety and top quality needs.

What Is the Ordinary Lifespan of Pipelines From Leading Manufacturers?

The ordinary lifespan of pipes from leading manufacturers normally varies from 30 to 100 years, depending on material, environmental problems, and maintenance methods. HDPE Pipe Manufacturing Texas. Routine assessments and adherence to industry criteria significantly influence longevity and efficiency

Exist Certifications Specific to Pipeline Manufacturing High Quality?

Yes, various accreditations exist for pipeline making high quality, consisting of ISO 9001 for quality monitoring systems and API standards particular to pipelines. These certifications ensure adherence to extensive safety, efficiency, and environmental requirements within the market.

Exactly How Do Manufacturers Handle Pipeline Maintenance and Repairs?

Manufacturers usually carry out a positive maintenance approach that consists of regular assessments, keeping track of systems for very early detection of problems, and a structured repair service protocol (HDPE Pipe Supplier). This technique guarantees pipeline honesty, minimizes downtime, and improves overall operational efficiency

Quality analysis in pipeline manufacturing pivots on 2 essential requirements: product toughness requirements and making process effectiveness. Material resilience requirements play a vital role in evaluating the high quality of pipes, determining the efficiency and lifespan of the materials made use of in building and construction. The products and making procedures employed by pipeline makers play a substantial duty in identifying the resilience of the final item. The average lifespan of pipelines from leading suppliers normally varies from 30 to 100 years, depending on product, ecological problems, and maintenance techniques. Yes, different certifications exist for pipeline manufacturing quality, consisting of ISO 9001 for high quality management systems and API standards details to pipes.